Industry Lighting: Professional solutions that provide safety, productivity, and energy cost savings.

In the area of industrial operations, the significance of proper lighting cannot be overstated. It plays a pivotal role in enhancing productivity, ensuring safety, and improving the overall well-being of employees. To meet the diverse and demanding requirements of industrial facilities, Luxiona offers an extensive range of tailored lighting solutions, spanning various crucial aspects, from optics to control systems, durability, and more. The wide range of solutions covers all of the industrial settings from production halls, industrial ovens and freezers, high and low rack warehouses, clean rooms to outdoor lighting.

Benefits of professional industry lighting

By implementing an optimal lighting solution, we can significantly elevate the standards of work quality, refine the precision of visual tasks, and bolster overall workplace excellence and safety. This multifaceted approach also encompasses the reduction of work-related accidents and the mitigation of production errors, by consequently amplifying employees' concentration, motivation, and productivity, especially those that work on night shifts.

Moreover facilitating efficeinet and flexible configurations translates into substantial cost savings and minimal maintenance requirements, all the while achieving superior energy efficiency when compared with conventional lighting systems.

Optical systems and light parameters

In industrial areas, machinery often operates with continuous movement or rotation. It's imperative that lighting quality remains consistent and that optical systems do not distort uniformity. Luxiona's lighting solutions are meticulously designed to prevent potential disruptions like overheating or lumen reduction caused by dust accumulation on luminaire surfaces, which can act as insulators.

Lowest UGR for comfort and safety

In windowless warehouses with closely spaced high racks, Luxiona places particular emphasis on achieving low Uniform Glare Ratios (UGR). This factor, in combination with correct luminaire positioning and uniform light distribution, minimizes sudden glare occurrences, reducing the risk of accidents during activities like forklift operation and goods stacking. Low UGR also contributes to the precision of work at heights, enhancing both safety and productivity.

Colour temperature and highest CRI

The colour temperature of lighting can significantly influence employees' focus, comfort, and well-being in manufacturing areas. As such, LUXIONA’s lighting solutions are thoughtfully engineered to address this critical factor. The colour rendering index (CRI) also takes precedence in Luxiona's approach. Depending on the specific industrial context, the value of the CRI can vary considerably, ranging from lower values, such as 70 in non-essential areas, to higher values like 90 and more, where precision is paramount. Luxiona's commitment to offering versatile solutions ensures that CRI is meticulously tailored to each environment.

Light ensuring employee safety

In industrial settings, exposure to ultraviolet (UV) radiation, especially outside the visible spectrum, can pose significant health risks to employees. Luxiona acknowledges the importance of addressing this concern and ensures their luminaires comply with the highest safety standards. Luxiona's luminaires typically rank in group 0, signifying that they pose no risk of exposure to employees according to the classification of this regulated under EN 62471:2009 norm.

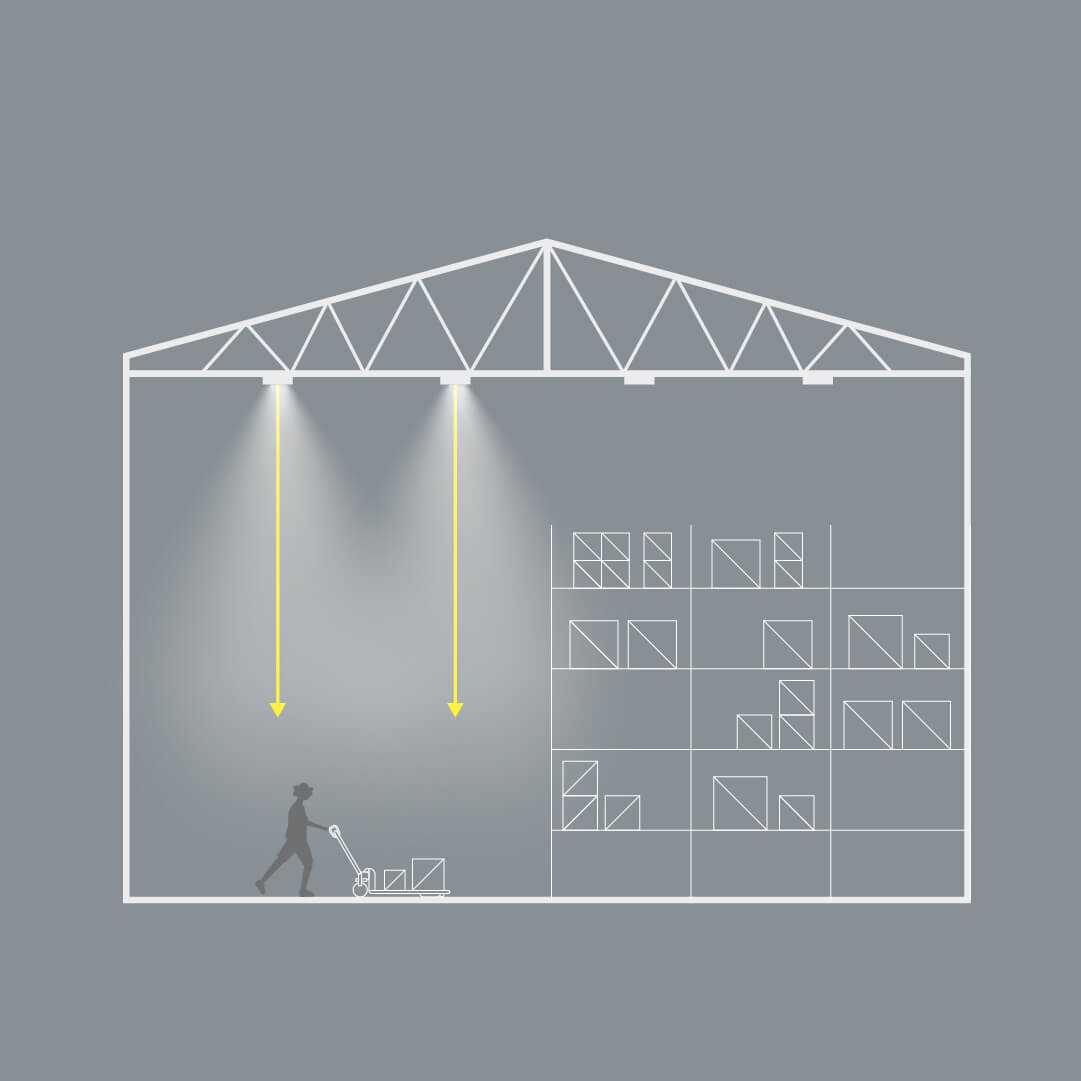

Light distribution for diverse spaces

Luxiona's industrial lighting solutions are designed to cater to a wide range of lighting distribution needs. Whether it's the narrow beam optics for vertical racking areas or wide beam angles for manufacturing stations, Luxiona offers a diverse range of luminaires to meet specific lighting requirements. A wide selection of tailored light distributions ensures not only visual comfort and safety but also improved productivity across all industrial areas.

Diffusers in different industries

Luxiona's product offerings include a diverse array of diffusers, ranging from high-resistant PMMA diffusers to optical sets based on lenses. These options cater to the unique needs of industrial and warehousing sites, considering factors like the presence of dust, corrosive gases, and cleaning products. Luxiona's adaptability extends to highly demanding industries, such as metal processing, wood processing and food industries where PMMA diffusers with high IP ratings are employed to prevent damage caused by oil vapors and metal dust ingress, and chemicals used in the production proces.

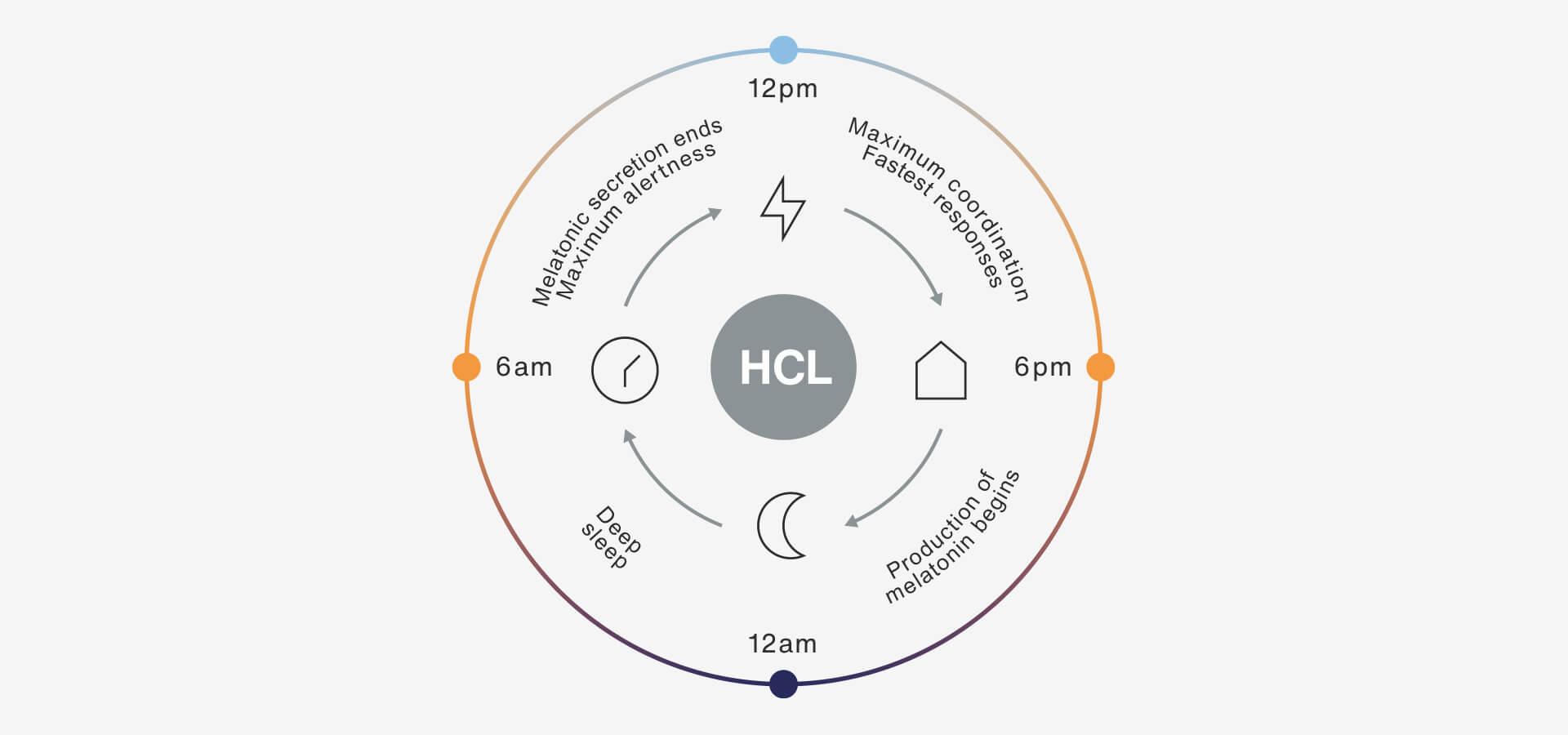

Human-Centric Lighting for well-being

Acknowledging the profound impact of lighting on human well-being, Luxiona embraces the concept of Human-Centric Lighting (HCL). By aligning four key dimensions of light—direction, color, intensity, and time of exposure—Luxiona's HCL solutions promote employee well-being throughout the workday. This approach is particularly crucial in warehousing and manufacturing spaces, where employees engage in repetitive tasks that demand ergonomic lighting conditions. Additionally, a well-designed lighting system can significantly reduce accidents by providing adequate illumination and enhancing overall safety.

Modular systems for adaptability

The adaptability of lighting systems is crucial in industrial settings where operations and configurations may change over time. Luxiona's modular and linear components and support rail systems enable effortless repositioning and rearrangement of luminaires. This versatility minimizes downtime during changes to the workspace layout or manufacturing processes, ensuring continuous productivity.

Luminaire bodies adapted to challenging environments

Luxiona takes into account the specific challenges posed by different industrial environments. Their customized luminaire bodies are engineered to withstand extreme conditions such as exposure to dust, high temperatures, corrosive agents, and reflective surfaces. By providing lighting solutions tailored to these conditions, Luxiona prioritizes employee safety and comfort.

Luxiona's industrial lighting solutions offer flexibility in terms of size, materials, and finishes. Each luminaire is designed to meet the specific requirements of a project, whether it's surface-mounted, recessed, or suspended. The materials used are chosen to withstand various conditions, including high temperatures, humidity, dust, and more. Customized finishes are also available, ensuring the longevity and performance of our products in diverse industrial settings.

Paper & wood manufacturing

Micrometric particles of dust, wood, or paper could be present in the air, increasing the risk of fire. In this case, luminaires should be temperature limited and also with high levels of lumen packages to compensate for the lost of luminance levels due to the accumulated dust or sawdust.

Corrosive ambiances

In farming or stables, and in any corrosive environment that emits gases ambiance, luminaires must be resistant to gases in order to guarantee a minimum lifespan by preventing both degradation of the body and ultimately damage to the LED sources because these corrosive principles getting in touch with phosphor coatings of COBS or SMD LEDs.

Hight-temperature rooms

Technical specs for luminaires used in high-temperature processing centers should minimise the risk of their components overheating. Our luminaires HT (high temperatures) are specially designed for installation in spaces with a very high ambient temperature (+50°C or even +60°C), such as industrial ovens. All components selected are sourced from the best manufacturers and are of the highest quality so that such conditions do not affect the lumianire's performance and lifetime.

Metal industry

Shiny surfaces affect UGR levels and unwanted reflections, which can pose a risk to workers operating metal-cutting machinery or workers who perform visual supervision of metal processing.

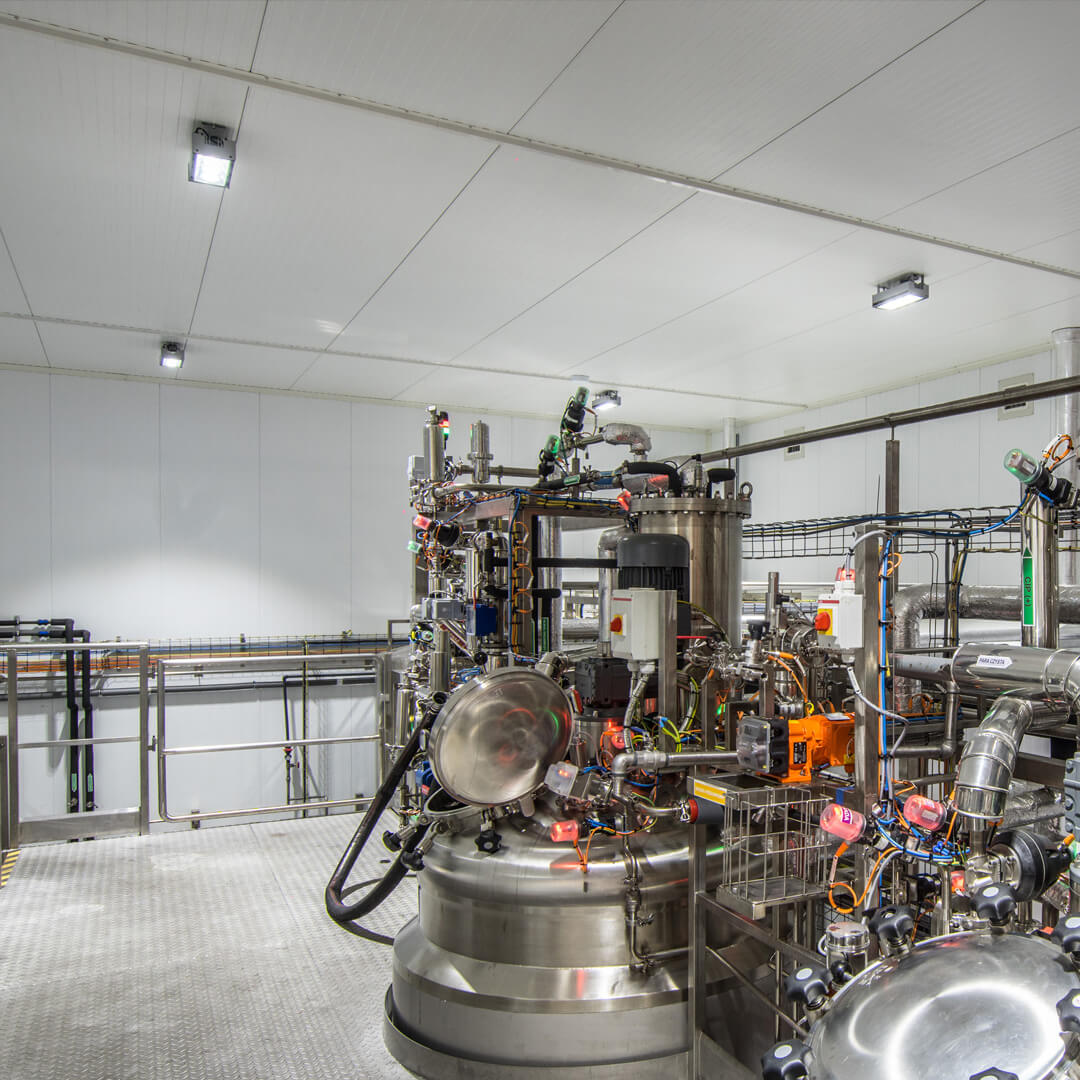

Food industry

At the top of the lighting technology requirements is the food industry, where glass finishes must be avoided and the surfaces of luminaires should be crack-resistant. The required levels of air cleanliness must also be met. Luxiona, as one of the market leaders in cleanroom lighting has machinery and specialised rooms for the manufacturing of clean and medical products, in accordance with its ISO 13485 certification.

High-temperature luminaires

Technical specs for luminaires used in high-temperature processing centers should minimise the risk of their components overheating. Our luminaires HT (high temperatures) are specially designed for installation in spaces with a very high ambient temperature (+50°C or even +60°C), such as industrial ovens. All components selected are sourced from the best manufacturers and are of the highest quality so that such conditions do not affect the luminaire's performance and lifetime.

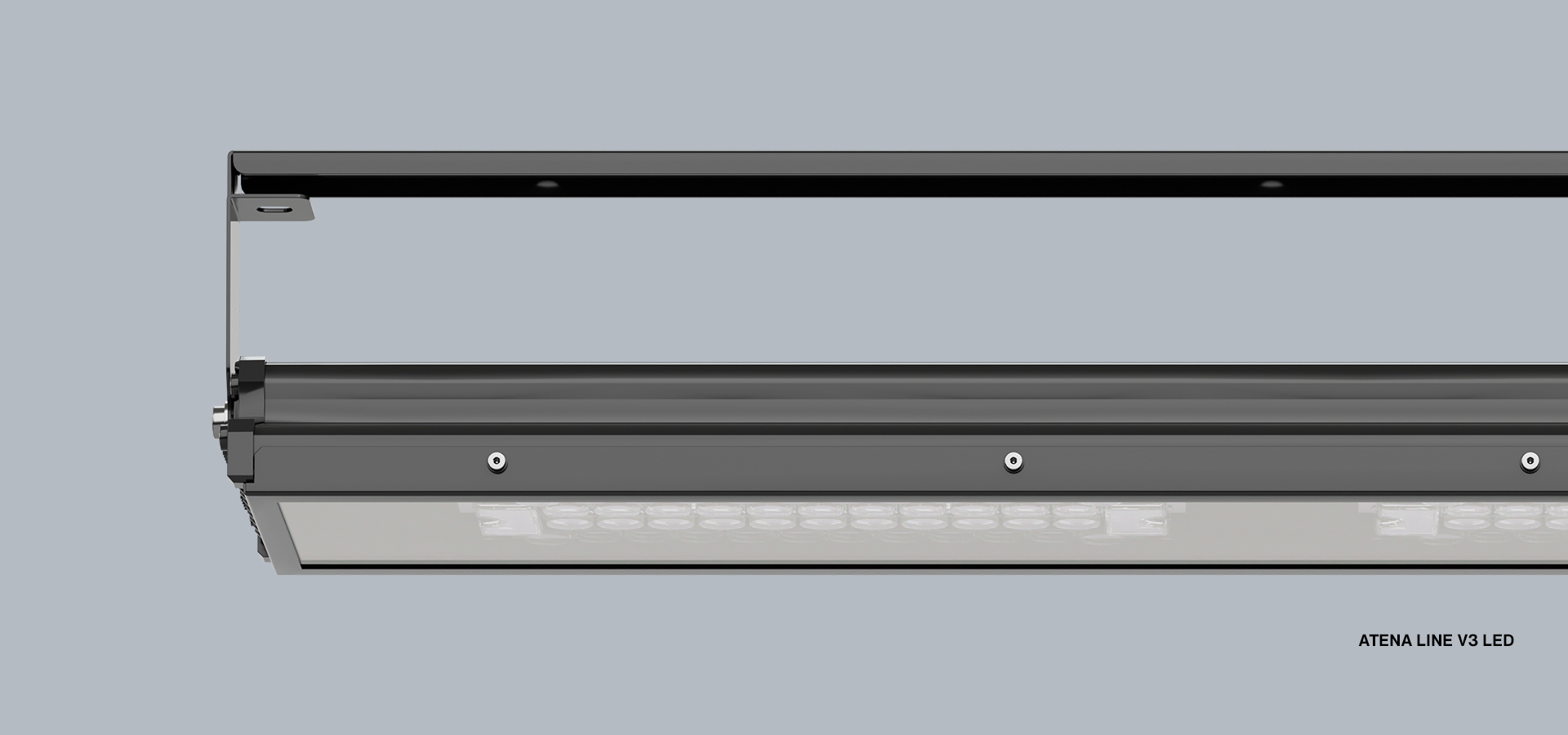

Mounted to ceiling construction or surface mounted on slings

Rectangular body made of specially designed aluminium profile

Cast aluminium end caps

Light sources protected by a dedicated lens

Possibility to choose optics with different light distribution

1. Mounted to ceiling construction or surface mounted on slings

2. Rectangular body made of specially designed aluminium profile

3. Cast aluminium end caps

4. Light sources protected by a dedicated lens

5. Possibility to choose optics with different light distribution

Optimizing energy savings in industrial spaces

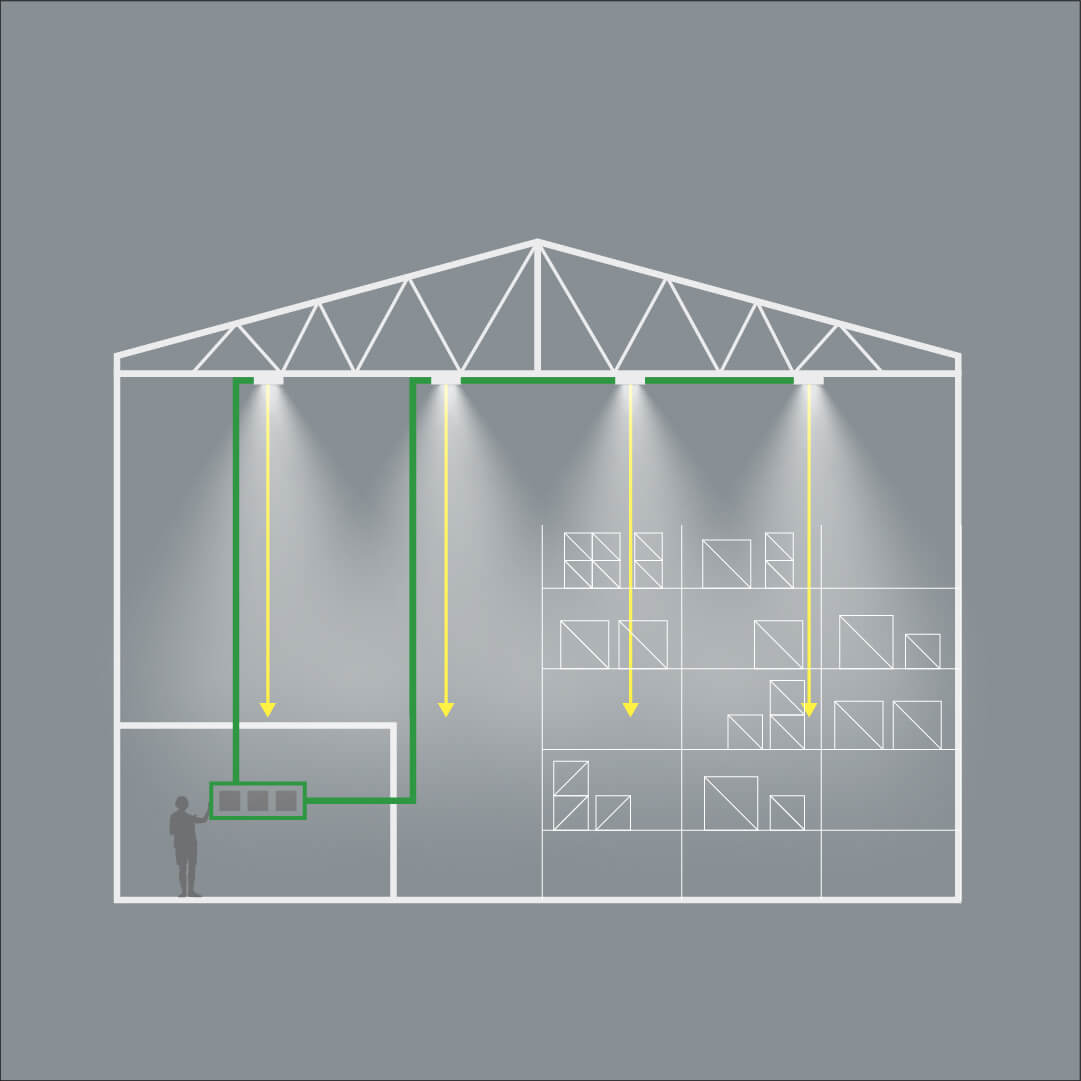

Combining LED lighting with intelligent control systems, such as CASAMBI or DALI, is a key strategy for achieving significant energy savings, in some cases up to 95%. These control systems allow for precise management of illuminance, dimming in response to available daylight, and detection of user presence. By harnessing these functionalities, Luxiona's solutions dynamically adapt to changing lighting conditions, resulting in substantial reductions in energy costs.

Presence detection

Presence detection technologies, like Passive Infrared Sensors (PIR), play a pivotal role in Luxiona's lighting control systems. These sensors detect user presence and activate luminaires as needed. If no user activity is detected within a predefined interval, the luminaires are automatically switched off to save energy. The user also has the option to manually control the luminaire when needed, further contributing to energy savings and optimizing room utilization.

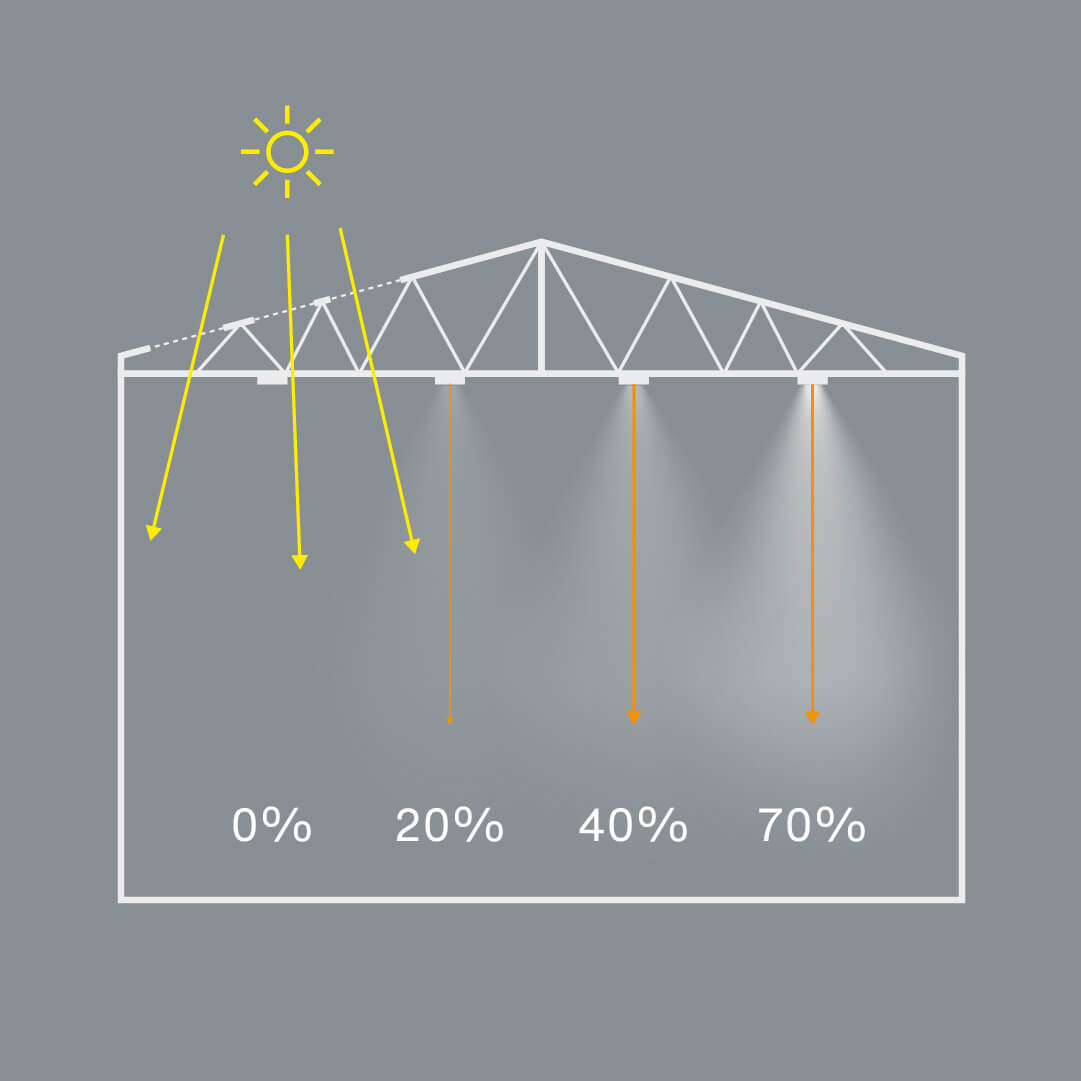

Harnessing natural light

By incorporating natural light sensors into your lighting control systems, you can enhance energy efficiency by responding to real-time lighting conditions. When natural light enters a room, the sensor detects its level and gradually adjusts the artificial lighting to save energy while maintaining the required illumination levels. This seamless integration of natural and artificial lighting optimizes energy savings, making Luxiona's solutions environmentally responsible and cost-effective.

Energy and traffic data

Thanks to centralizing lighting infrastructure for efficient management and creating a smart network, facilities you can maximize energy efficiency and reduce operating costs. Intuitive software or apps enable real-time monitoring of system status, energy consumption, employee movement, and early detection of failures. This real-time data provides insights into power consumption, natural lighting levels, and employee activity, allowing for flexible adjustments to lighting parameters and ensuring top-tier lighting quality.

Durability and sustainability

In high-ceiling industrial settings, the durability of luminaires is paramount. Luxiona recognizes that a high lifespan for lighting fixtures is crucial for reducing maintenance costs and ensuring uninterrupted operation. Their commitment to longevity extends to all aspects of their products, ensuring they withstand the rigors of industrial environments.

Flux maintenance & longevity

The longevity and quality of Luxiona's products often exceeds industry standards. Flux maintenance values of L80B10 after 100,000 hours of operation indicate that even after extensive use, Luxiona's lighting solutions maintain a high level of luminous flux, thus reinforcing our dedication to quality and durability.

Environmental responsibility

LED lighting minimizes energy consumption, emits less heat, and is free from harmful substances. This commitment to environmental responsibility enhances a brand's image and aligns with sustainability objectives. Businesses can earn recognized green certifications for their facilities and production areas by reducing carbon emissions.

New Bonanova solution and novelties in the Neptun family

LUXIONA's latest industrial lighting solutions offer advanced features like high-temperature resistance, ensuring reliable performance in demanding environments, as well as incorporate innovative solutions to simplify maintenance and facilitate easy dust cleaning, making them the ideal choice for modern industrial facilities seeking efficient and long-lasting solutions.

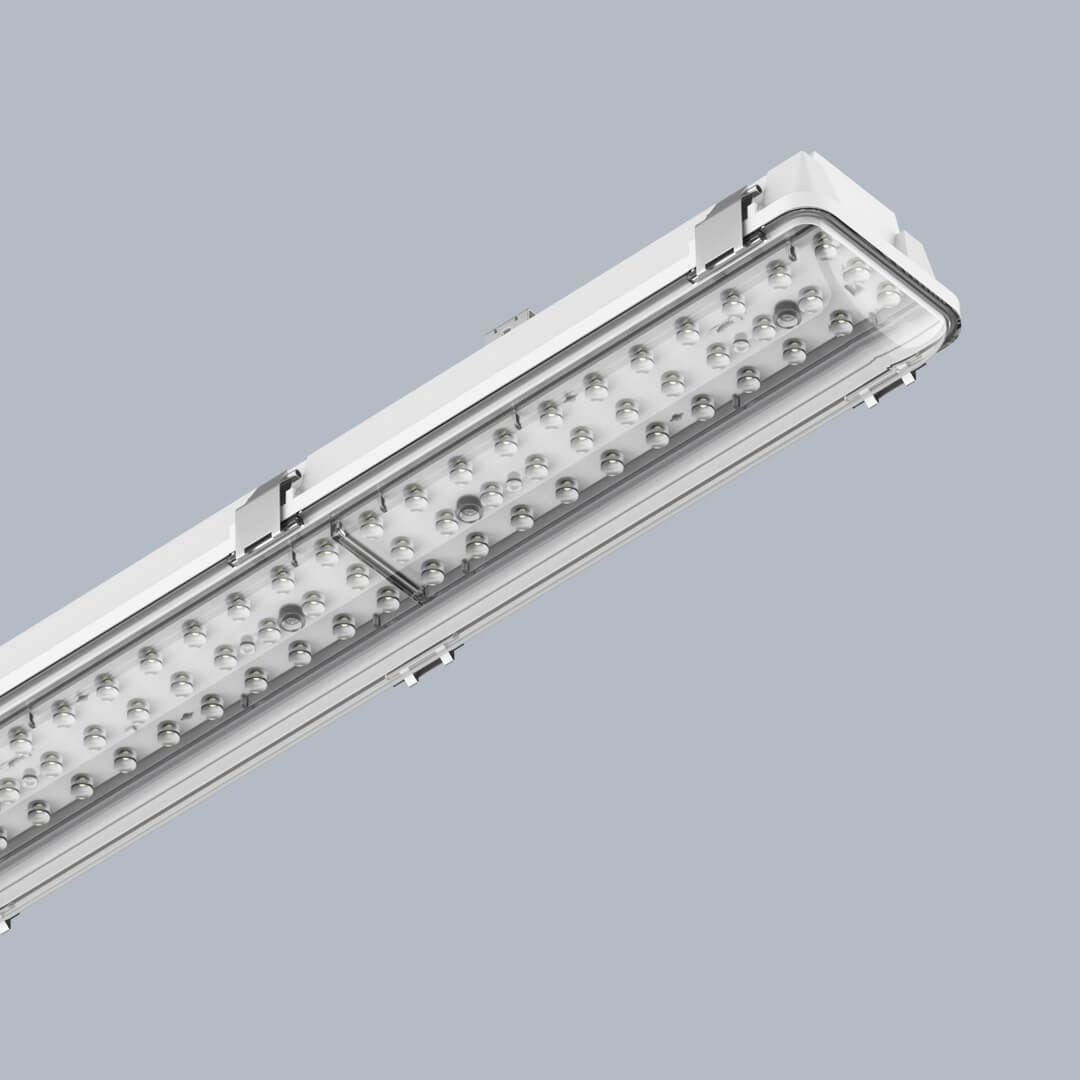

Neptun Industry

Introducing the latest addition to the Neptun family: Neptun Industry, a waterproof luminaire now available in an even more resilient version designed to thrive in extreme temperature environments, ranging from -25°C to +60°C. This versatile luminaire comes with various lens options, including 30º, 60º, 90º, AREA, ASY, D-ASY, and Oval, providing tailored lighting solutions for diverse industrial needs.

Bonanova

New Bonanova, an innovative lighting solution with a focus on versatility and performance. This luminaire with a sleek housing design without the need for external heatsinks offers a range of installation options to suit various industrial settings. Its design effectively prevents dust and dirt buildup. This not only ensures optimal performance but also extends the lifespan of its components.

Acoustic Solutions:

Elevating Comfort and Productivity with Sound-Absorbent Luminaires

Lighting Modernisation:

Sustainability and savings thanks to the lighting replacement

Retail Lighting:

Bring out the best in your retail space